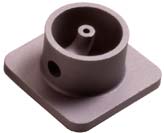

Investment Castings

For over 65 years, our manufacturers have served the OEM market for investment cast metal parts. Featuring the patented lost wax process, we offer near net shape, close tolerances, and excellent surface finish which means reduced costs for materials, machining, subassembly, fabrication and other secondary operations.

Specializing in small parts ranging from fractions of an ounce to 10 pounds, we offer nearly 200 ferrous and non-ferrous alloys including aluminum, ductile iron, carbon, low alloy and stainless steel, copper-based alloys and magnesium alloys.

- Near Net Shape

- Design Freedom

- Weight Reduction

- Tooling Economy

- Surface Finish

- Wide Alloy Choice

On average, investment castings offer 90% or more of the requirements of the finished part in an as-cast state. Investment casting can incorporate complex undercuts, slots, holes, lettering, and bevels into the design. We work closely with you to determine whether it is more cost effective to build desired features into the die.

In addition, we can provide individual prototypes or very short run parts directly from solid model files, without the need for expensive tooling.

Material Selection for Flexibility

Providing you with unprecedented resolution, surface finish and dimensional accuracy, we pour these alloys in addition to all air meltable alloys:

- Casts 47-50

- Hastalloy, Inconel, Monel, and Nickel X

- Tool Steels

- Ingot Iron (Armco) & Silicon Irons for special applications

- Beryllium Copper

Secondary services include heat treating, machining, coating, plating, painting, and simple assembly.