Metal Stampings and Fabrications

Dace & Dace brings you the very best tool and die manufacturer for custom metal stampings, sheet metal fabrications, stamped assemblies, and in-house precision tooling, ISO, TS, & AS certified facilities are utilized.

Whether your forming needs include short runs, medium runs, or long runs, we have the source and solution for you including laser and waterjet cut and/or custom designed, high quality metal stamping dies and stamped metal products.

For cost saving, innovative ideas, a team of experts will review fit, function, design, and volumes presently used with an emphasis toward an overall cost reduction.

Our team can help you engineer and build stamping prototypes and then transition you to production.

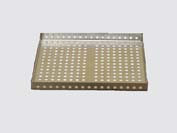

Short Run Stampings

The original concept of “short run stampings” involved a very special tooling process developed more than 70 years ago to produce high quality metal stampings with a specific pattern of routine operations, all designed to keep tooling costs at an absolute minimum.

Our tool and die manufacturer provides you with short runs (25-25,000 pieces) with all tooling built in-house. Tooling consists of over 178,423 standard engineering fixtures that can be used and customized at either no or very low cost to you.

Presses from 18 tons to 215 tons

Our custom metal stamping expertise and sheet metal fabrication technology provides a resource for complete “unlimited” metalforming service. Most shapes can be blanked, pierced, formed, stenciled, drawn and extruded.

Our forming manufacturer also stocks the most common thicknesses and tempers of cold rolled steel, aluminum, stainless steel, brass, copper and many other materials.

Precision Progressive Die Stampings

Progressive die stamping utilizes multiple cutting and/or forming operations simultaneously. This helps maintain close tolerances while saving time and money by combining forming operations.

Providing you with precision long run stampings (up to the millions) with the option to hold stock for JIT (Just in Time) delivery per your requirements.

Presses from 2 tons to 600 tons

Specializing in automated precision progressive dies, you have access to Link Motion Technology & Servo Press Technology, with feed capability ranges from 0.008 to 0.375 inch thick material and coil widths up to 50 inches wide and weights to 15,000 pounds.

Providing you with a fully capable in-house tool room, expertise in CNC wire capabilities, tool and die build, and years of experience in building progressive dies, fixtures, machines, in-die assembly and automated secondary process precision tooling. Our tool design experts specialize in manufacturing and maintaining progressive dies to create tight tolerance end products.

Fabrications

Offering you low volume/high mix sheet metal fabrications from small parts to large custom metal enclosures, NEMA enclosures, weldements, and complex assemblies to further enhance our precision forming capabilities.

Fabrication capabilities include but are not limited to:

- CNC Turrets

- CNC Machining

- NC Press Brakes

- Robotic Welding

- 4,000 Watt Laser

- Water Jet

- EDM

We can provide you with a full range of secondary services such as assembly, forming, riveting, degreasing, laser cutting, heat-treating, anodizing, CNC machining, drilling, tapping, painting, plating, welding, bar coding, belt sanding, deburring, reaming, countersinking, silk screening, polishing, and powder coating.