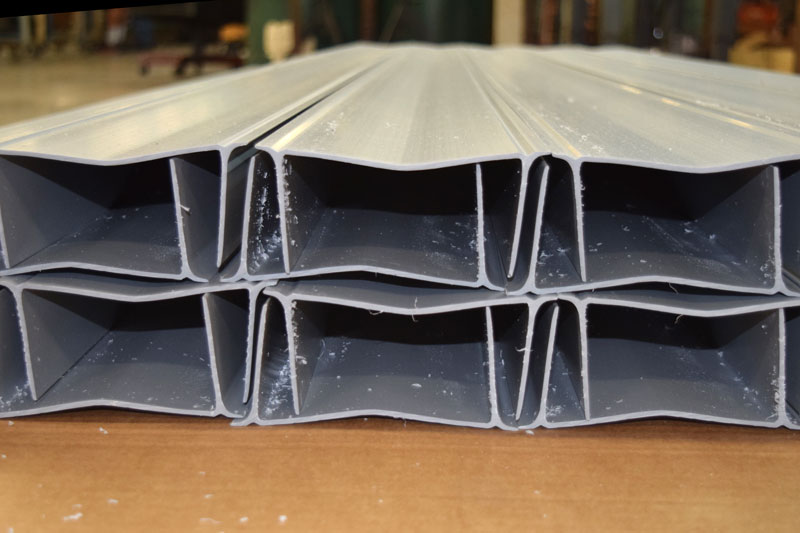

Plastic Extrusions

This process can offer a cost savings alternative to injection molding or machined metal. The success of any custom plastic profile extrusion relies on getting this first step right. Our team of design engineers will listen to your need and create innovative solutions that exceed your expectations.

- Design Assistance

- Material Recommendation

- In-House Tool Development

- Equipment Expertise - Single screw extrusions to vacuum calibrated complex twin screw extrusions

Materials

Choosing the right materials will turn those concepts into superior products. The ingredients used in manufacturing your product are critical.

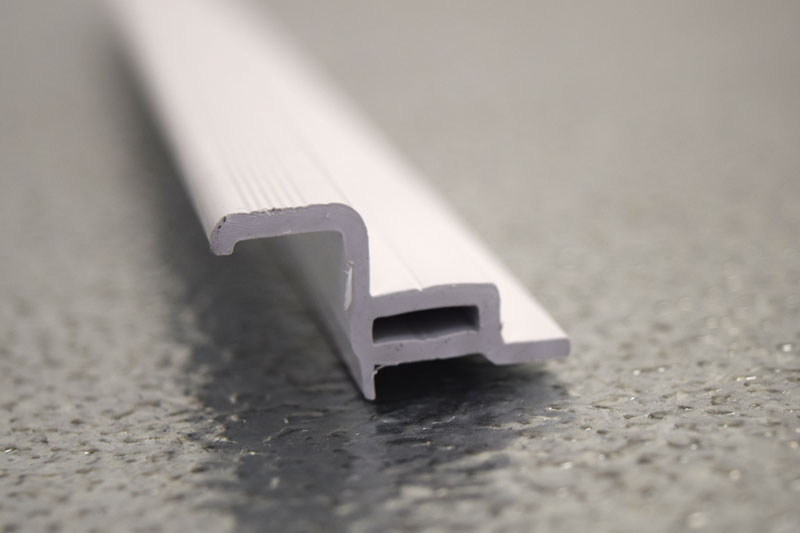

- Rigid PVC

- Flexible PVC

- Acrylonitrile Butadiene Styrene (ABS)

- Thermoplastic Elastomer (TPE)

- Polyethylene (PE)

Capabilities (In-Line)

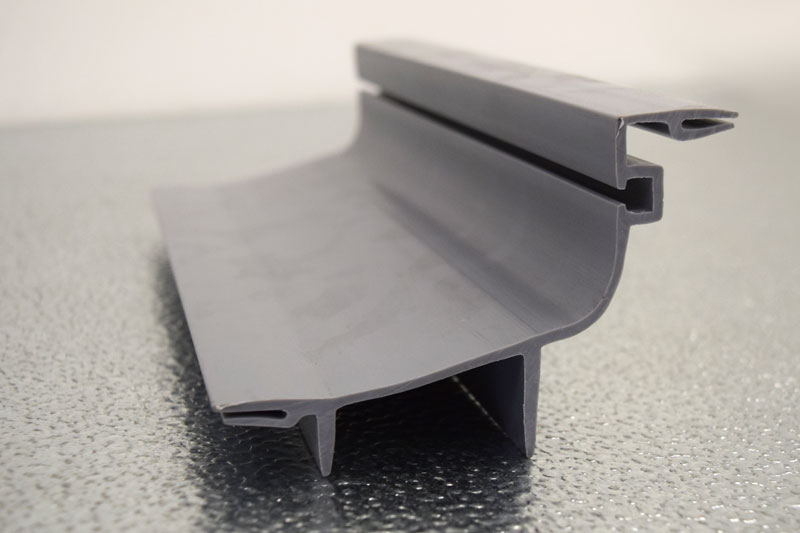

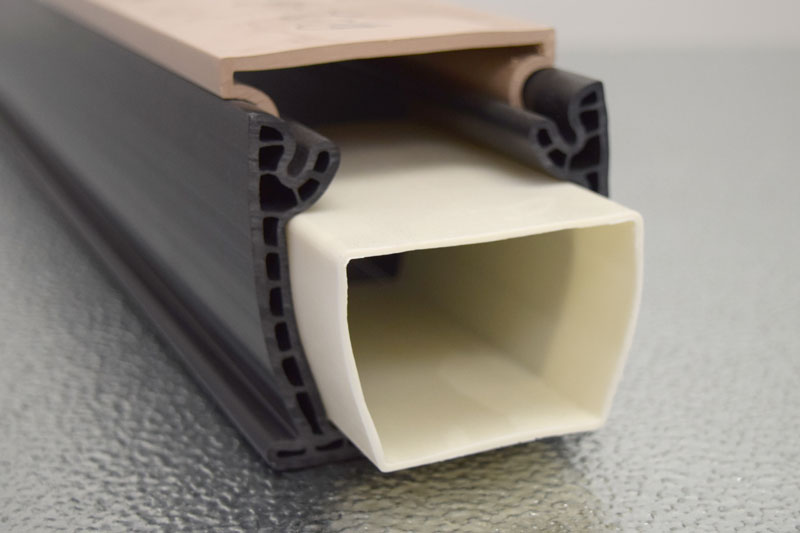

- Dual and Tri-Durometer Extrusions

- Co-Extrusions

- Film Lamination

- Vacuum Sizing

- Punching

- Printing & Embossing

- PSA Tape

Also, sonic welding, routing & notching, die cutting, drilling & tapping, punching, and assembly. We also offer special packaging needs, kitting and distribution to meet all your business deliverables.

From simple flexible tubing to elaborate Rigid PVC extrusions, we have the experience to produce quality product in a timely manner.